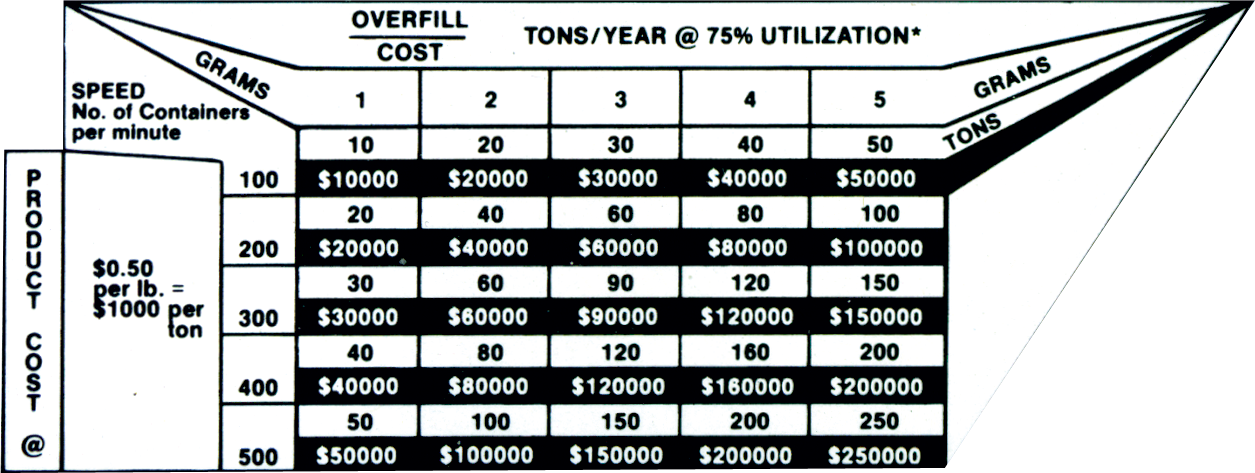

Elmar patented “Individual Piston Stroke Adjustment” is a technology developed uniquely for Elmar Rotary Piston Fillers. Each domed piston slide block contains the mechanism to enable micro-adjustment to be made to increase or decrease by a few grams either way the volume of the product dispensed. Because each piston can be adjusted individually, the range or spread of overfill when filling is virtually eliminated. The result? Our clients save thousands per year.

The table below shows the weight/cost of product lost in tons per year by over filling each container by 1-5 grams. This is based on fifty 40 hour weeks or 2000 hours.

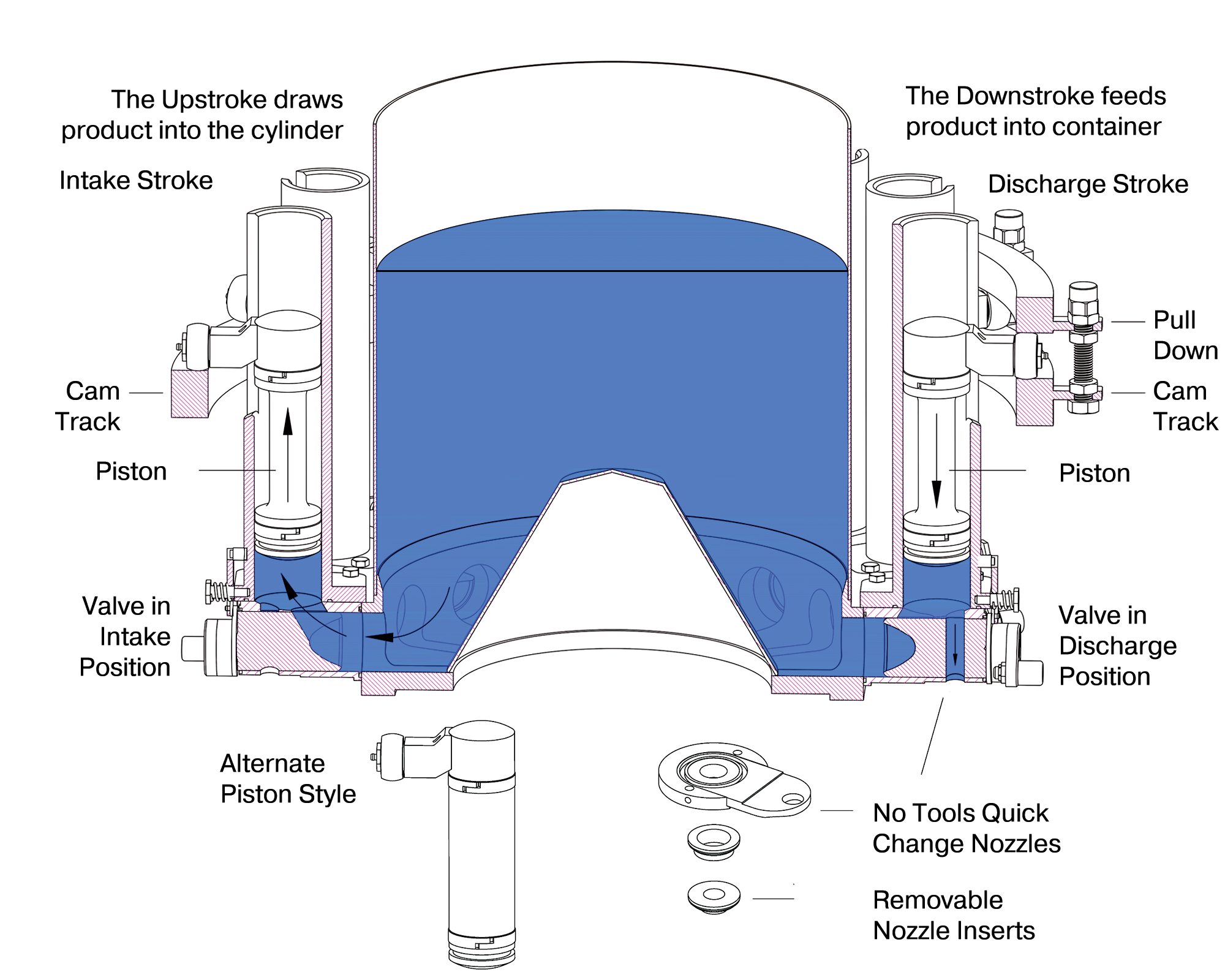

The action of the piston and valve are shown above. As the filler rotates, the product is drawn through the intake passage in the valve, into the cylinder, by the upward motion of the piston being raised by piston roller operating on the cam track. With a container present, the valve is rotated closing the intake port and opening the discharge port. The downward stroke of the piston forces the product through the discharge port into the container. At the completion of the stroke, a cam returns the valve to its’s original position closing the discharge port and opening the intake passage. The the process is repeated.